CLEANING HP Z3100 - Z3200 Printheads,

manually and internally

(Above), each HP Z Series printhead comes in it's own tub and has

orange protective caps that keep the printheads moist and

free of dust.

(Above), the "business end" up - the section of each printhead

(nozzles) that

ink squirts through. Note the electrical contacts on the

left.

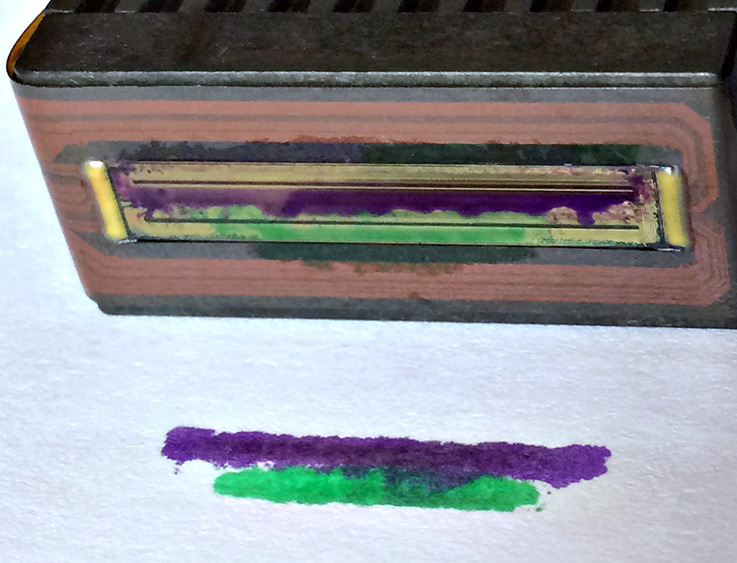

(Above), closeup of HP 70 printhead showing the two sides, or double heads

with two colors. Each printhead has a trough of ink

and as it becomes used, over time the heads become clogged

and ink builds up. If the printer sits idle for too

long, this is what results - commonly referred to as

"clogged printhead", or "clogged nozzles". Sometimes, through the head

printer cleaning routine, a printhead can be unclogged, but

more often than not, more drastic measures are required to

make a printhead become unclogged and fully functional.

If it takes too much cleaning to bring a printhead back to

life, then to me, it's just not worth it. Since

printheads cost less than half the price of a new 130 ml ink

cartridge, it becomes expedient to simply replace the

printhead with a new one. Clogged printheads can

become a real pain, and sometimes it is just not worth the

time to mess with them.

Still, in all, if some are frugal, or in a jam, there are

methods to make them work.

I prefer to use a combination of internal printer head

cleaning and manual cleaning and wiping. HP is careful

in their instructions, recommending that little to no wiping

be done on a print head, but I have had success in certain

cases, as have many on the web who advocate printhead

cleaning.

Here are HP's instruction about cleaning:

Gather the appropriate

cleaning materials:

Any clean, soft, lint-free material that will not come apart

or leave fibers behind when wet (coffee filters work well)

Enough distilled, filtered, or bottled water to moisten the

cloth. Avoid using tap water, which could contain damaging

contaminants

Paper towels, or sheets of paper to rest the printheads on

during cleaning

Gently wipe the printhead contacts with a dry, clean, soft,

lint-free cloth.

If some residue remains, slightly moisten the cloth with

distilled, filtered, or bottled water and continue wiping

until the contacts are clean.

The most successful method I have used

time after time is this:

Put just the bottom of the offending

printhead in a small tray of warm water under the sink.

Continue soaking the bottom of the print head, occasionally

cleaning the bottom with a lint free cotton cloth.

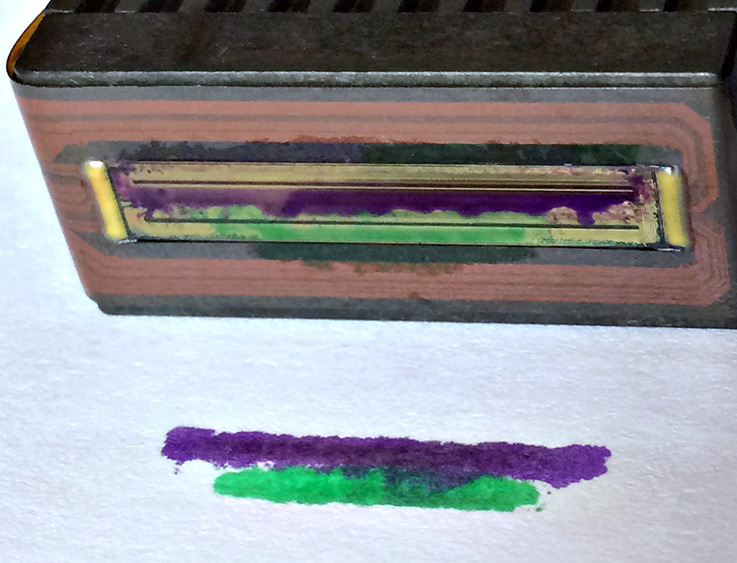

After 15 or 30 minutes, dry off the print head and "stamp" a

folded over paper towel.

Look carefully at the pattern. If the print head is working

right, a consistent line of blue and green (if it is a BG

head) will show up perfectly. If there is a clog, only part

of the line will show. Compare the lines side by side,

looking carefully. These line patterns will correspond

exactly with a diagnostic image. Keep soaking and cleaning

until the printhead shows a clean stamp pattern.

I worked for an entire day on the printhead above and could

not get a perfect stamp. Of course one could keep

going and keep trying and maybe, perhaps, possibly, get

there, but I broke down and just ordered a new printhead.

It's easy to think that "maybe the next trick will work",

but not necessarily.

Windex as a next step sometimes works, but be aware,

isopropyl alcohol, nail polish remover, etc., will likely

get you into trouble.

A youtube video explains how to

clean printheads seven different ways:

7 WAYS TO CLEAN PRINTHEADS

READING AND

UNDERSTANDING HP Z SERIES PRINTHEADS AND CHARTS

The key to cleaning print heads on HP Z Series printers is

to be able to know what is actually wrong with the

printheads at any given time. The only way to

accomplish this is to be able to view a graphic

representation illustrating what each printheads is doing

and how it is performing.

HP has created a utility program to enable internal cleaning

of the printheads from the front panel of the printer and an

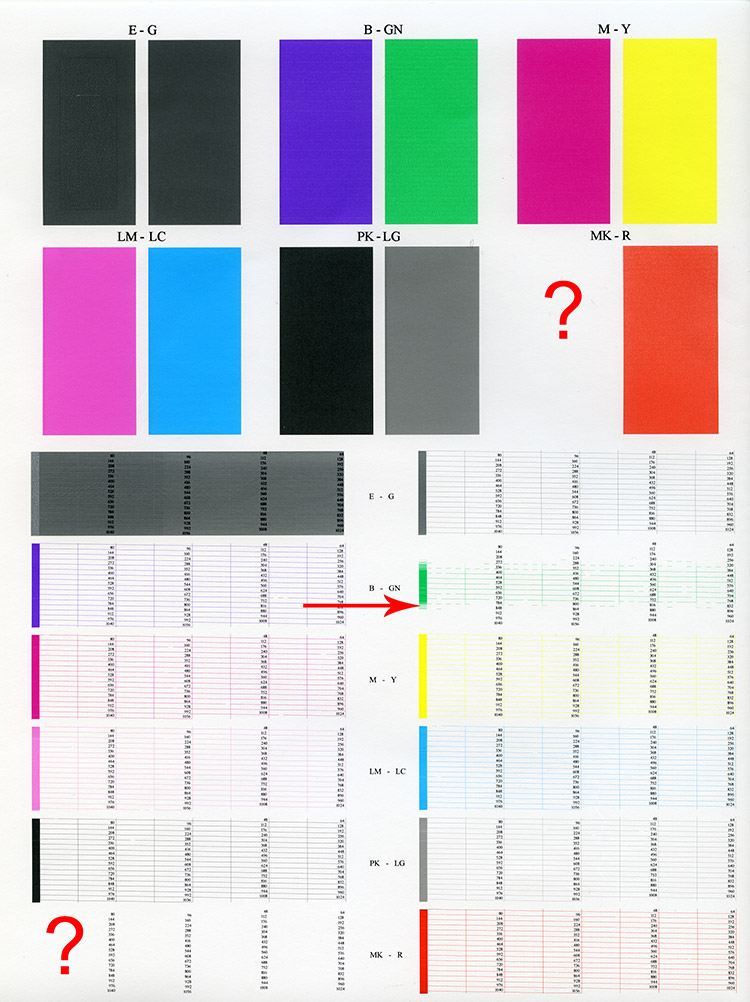

option to print out a diagnostic chart. Below, is a

diagnostic chart that clearly indicates problem areas with

several printheads. Each print head uses two colors,

for example Blue and Green, Magenta and yellow, etc.

One print color can be printing perfectly and the other

might be totally inoperable. Each HP 70 ink printhead

has two compartments for ink and corresponding print heads

beneath that the ink is squirted through.

Notice in the chart how the horizontal lines and washed out

colors clearly illustrate the areas where ink is not passing

through the printhead. In the color patches on top,

the colors should be solid and filled fully. In the

linear diagrams beneath the color patches, notice how the

lines should be solid on the left, and in the horizontal

lines to the right of the vertical lines they should also be

solid and well defined. Each area of the chart is

designed to correspond directly with where the printhead is

malfunctioning.

When I first started with a 24" Z series printer that was

given to me, barely any colors were showing at all on the

diagnostic chart. It took several weeks of printhead

cleaning, manually and internally, and in a several cases

replacing the printheads until the colors came back fully on

the printhead diagnostic image. The chart below shows

gradual progress, but indicated areas of malfunction -

arrows in red point out clogged areas. Notice that entire

areas of color are missing.

Each time a printhead is seated or reseated from the panel

install, with prompts, a printhead calibration chart (printhead

alignment chart) is automatically generated. Notice

the green areas which show areas of non-function.

These charts can be made with just about any paper, but

glossy papers show the areas best, and the charts become

easier to read.

The green areas on the charts above and below, correspond

directly with the "stamped" pattern of the actual printhead

(below). You can take any printhead, and stamp it on a

folded over piece of paper to diagnose directly where the

printhead is malfunctioning.

In the last chart, below, almost all problems have been

cleared up and the printheadsw appear to be printing well

and as normal. Scroll back to the top chart, then back

here, and it clearly illustrates how far the cleaning and

replacement process journeyed to get back to normal.

Here is a tried and true technique that I use when I have

issues with a printhead and need to get back printing ASAP

(before a new one is delivered):

Take all the heads out, (by opening

the cover, and when the printhead carriage is in the correct

position, turn the back main power toggle switch off, then

unplug the unit). Squeeze and vigorously shake each

printhead, and one by one, blot, then replace, until all

printheads are reinstalled. It helps to clean up the

interior of the printhead carriage and to clean the

contacts, etc. Close the window, plug the cord back

in, then run a printhead alignment, then a full head clean

for all printheads, then print out a diagnostic image.

This method works well up to a point in bringing it the

printheads back to life. If there is just one

troublesome printhead, no need to pull them all. If

you pull them all, it is likely to improve overall.

The diagnostic charts are your friend - learn to read

and understand them.

Once a chart looks like the one above, further tweaking can help, but

afterwards, getting that last few percent is difficult, and

could perhaps only be achieved by replacing all the printheads with new ones. This is the goal,

however; to have a clean diagnostic chart, a clean printhead

alignment chart, and the assurance that the printheads are

working as designed.

Bear in mind, according to HP:

The Nozzle Print Test test is

designed to check if the Printhead nozzles print correctly.

The diagnostics test prints out every single nozzle of each

Printhead without applying an error hiding or alignment

algorithm.

For each Printhead, you can see both the adjacent and the

consecutive nozzles.

If any nozzles are not printing correctly they will be shown

on the right of each Printhead Nozzle test.

There is a series of numbered stepped diagonal lines. If one

or more of the nozzles are clogged, malfunctioning or mis-

positioned, you will see that the stepped lines are broken

or misdirected in one or more places.

(For example), [if]... the stepped lines highlighted in

yellow are broken. When the line is completely broken, this

means the nozzle is out.

(For example), [if]..., the stepped lines highlighted in

yellow are misdirected. When the line is misdirected, this

means the nozzle is malfunctioning or out of position.

Print Quality

On the left of each Printhead Nozzle test, there is a series

of horizontal straight lines. If one or more nozzles are

misdirected there will be unequal spaces between the

corresponding lines.

Corrective Action

If the printer has nozzle defects, you can still get perfect

print quality results. The printer can automatically

compensate for nozzle defects, so there is no need to

replace the Printhead.

The method of improving Nozzle Defects is to:

1 Recover the Printheads, using the Front Panel Main

Menu/Image Quality Maintenance/Clean Printheads option.

2 Reprint the Printhead Nozzles Test Plot to verify that the

defective nozzles have been corrected.

3 If the problem continues, replace the defective Printhead.

Corrective action, of course varies, and particularly

depending on your schedule and availability of a new

printhead. If you want to play it totally safe - just

go buy a new printhead and follow instructions. Keep

in mind that just changing the printheads out is not always

the answer. Other problems such as clogged ink tubes,

and other "cans of worms" can be the culprit.

Usually, however, just doing thorough

cleaning and judicious printhead cleaning and/or

replacement, and most of all, keeping the machine ON

24/7/365, does the trick.

*NOTE:

If any of the ink cartridges are low on ink when replacing

the printheads, the printer may think the new printhead is

faulty when actually it is that the ink cartridge is too low

to fill the new printhead. Always have cartidges that

are mostly (at least 1/2) full when replacing a printhead or

you might get the error message to replace the printhead.

PRINTING TEST IMAGES

Perhaps the gold standard of test images is what

photographers and printers

commonly refer to as:

"The Atkinson

Printer Profile Test Image"

|

What made this chart so successful (which is still

used by hundreds of thousands of photographers today) beyond

its intended use, is that

it presented a wide array of colors and tonal ranges.

What made it most valuable is that it organized and

quantified color in a coherent, readable print. If the

images looked right, then your profile and color workflow

was probably right.

A similar chart can be made from your

own photos. If you know them well, you can organize

them similarly and you'll be able to tell if they look right

to you when the whole page is printed out.

Search the internet for test images made by

photographers. They frequently post them to download

and print.

*The Atkinson image above is copyright Bill Atkinson.

It is being used in an educational capacity in this context.

Search the web for more information and a larger chart.

Printer exercise images

Certain images can be used to exercise your printheads.

If a printer is left sitting for prolonged periods of time,

it's a good idea to run a printhead exercise print once a

week.

Below is my printhead

exercise print, free for download.

Click image above for larger print image

(These are my own personal notes from repairs I have

made.

I have made this web page for my own benefit, so I have a

record of what I have done.

If you use this information, do so at

your own risk - I assume no responsibility for errors.)

|